Ordinary centrifuge

- 产品描述

Characteristic:

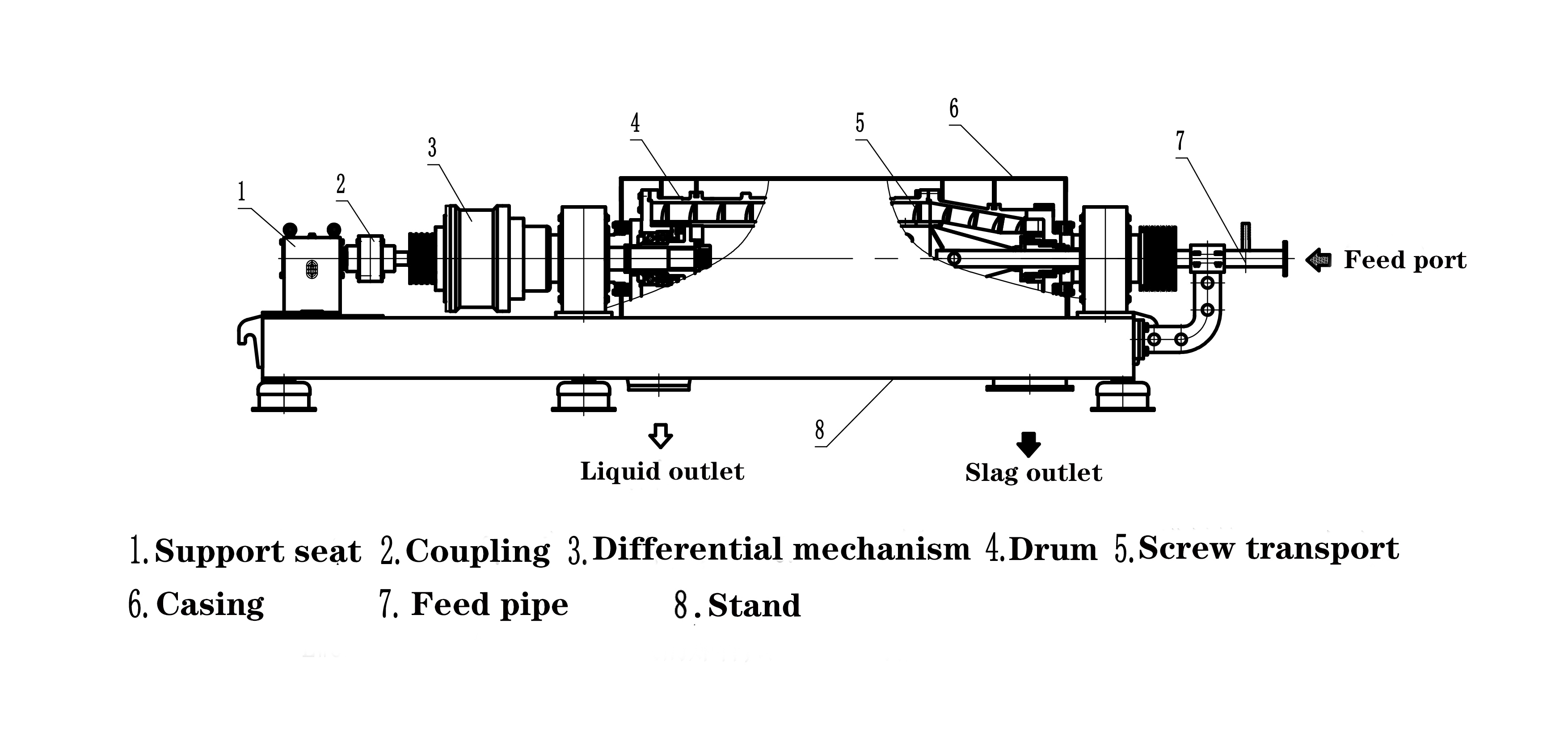

LW series horizontal spiral discharge sedimentation centrifuge is a kind of mechanical equipment which uses the principle of centrifugal sedimentation to continuously separate the materials with density difference in suspension. The basic principle is: the drum and the feeding screw rotate at a certain differential speed, and the material is continuously introduced into the inner barrel of the screw pusher by the feeding pipe. Under the action of the centrifugal field, the heavy solid phase deposits on the drum wall to form a sediment layer. The solid phase is continuously pushed to the cone end of the drum by the feeding screw pusher. After dehydration in the drying area, the solid phase is discharged out of the machine through the slag outlet. The lighter liquid phase forms an inner liquid ring, which continuously overflows the drum from the overflow outlet of the big end of the drum and is discharged out of the machine through the outlet. The machine can continuously complete the feeding, settling, separating, dewatering and discharging processes under full speed operation. It has the characteristics of compact structure, continuous work, stable operation, strong adaptability to separated materials, large production capacity and convenient maintenance. It is suitable for the separation of suspensions with particle size larger than 0.005 mm and concentration range of 0.2-40%. Widely used in chemical, light industry, pharmaceutical, environmental protection and other industries, with environmental protection, energy saving, consumption reduction, reduce labor intensity and other significant advantages.

Application:

It is suitable for the separation of suspensions with particle size larger than 0.005 mm and concentration range of 0.2-40%. Widely used in chemical, light industry, pharmaceutical, food, environmental protection and other industries. For example: oxalic acid, alum, aluminum hydroxide, ammonium bicarbonate, ammonium chloride, ammonium sulfate, anthracene, antibiotics, barium chloride, barium sulfate, benzene, benzoic acid, blood products, blue alum, borax, wine tank, calcium carbonate, calcium citrate, calcium hydroxide, calcium nitrate, casein, cellulose, chrome yellow, clay, methylcellulose, coal flotation waste, corundum, cotton wool, corn germ Starch, coconut juice, edible oil, fish processing, mirabilite, glutamic acid, hops, pesticides, diatomite, herbicides, tartaric acid, sodium sulfate, sodium phosphate, sodium nitrate, sulfuric acid residue, carbon black, etc.

Main technical parameters:

Series Maximum speed Highest separation factor Motor power Treatment capacity LW400 Series

(single motor)

LW400*1200 (Made of 304, 321, 316L, 2205, 2507 and other stainless steel materials) 3800~4500r/min 3246~4530

15~45KW

2~5m³/h LW400*1400 LW400*1600 LW400*1800 LW450 Series

(dual motor)LW450*1350 (Made of 304, 321, 316L, 2205, 2507 and other stainless steel materials) 3200~3800r/min 2580~3640 22~45kw

5~20m³/h LW450*1575 LW450*1800 LW450*2025 LW520 Series

(single frequency conversion)LW520*1560 (Made of 304, 321, 316L, 2205, 2507 and other stainless steel materials) 3000~3500r/min 2620~3560 45~85KW 8~14m³/h LW520*1820 LW520*2080 LW520*2340 LW600 Series

(double frequency conversion)LW600*1800 (Made of 304, 321, 316L, 2205, 2507 and other stainless steel materials) 2400 ~ 3000r / min 1935~3020 55~85KW 10~18m³/h LW600*2100 LW600*2400 LW600*2700 LW810 Series

(closed type)LW810*2430 (Made of 304, 321, 316L, 2205, 2507 and other stainless steel materials) 2000 ~ 2600r / min 1792~3060 122~200KW 75~130m³/h LW810*2835 LW810*3240 LW810*3645 Structure diagram:

Ordering instructions:

Material: carbon steel, stainless steel, titanium alloy can be used in contact with the material.Wear-resisting treatment: the screw can be sprayed with wear-resisting material, inserted with cemented carbide and inlaid with corundum ceramic. Slag discharge opening can be inlaid with carbide sleeve and corundum ceramic sleeve.

Structural form: complete flow

Speed regulation: stepless speed regulation of drum speed, stepless spiral differential, stepless.

Bearing lubrication: choose grease, thin oil lubrication, thin oil forced circulation lubrication.

Safety protection: vibration protection, bearing temperature online detection, display and overheating protection, oxygen detection, etc.

It can be designed and manufactured according to GMP standard or special requirements of users.

CONTACT INFORMATION

联系方式

OFFICIAL ACCOUNTS

公众号

欢迎关注我们的官方公众号

ONLINE MESSAGE

联系方式

Copyright ©2020 Zhejiang Dajin centrifuge Co., Ltd. 浙ICP备12027601号-1 浙公安备 33060402000844 Support:Tsheng